Metal-working

Increase the lifespan of your machinery and the quality of your production

Water treatment in metal-working facilities prevents the corrosion of both the product and machinery. This immediately increases production quality and reduces maintenance costs.

We manage water for these companies

What problems can be caused

by inadequate water treatment?

Corrosion of metalwork

If the water you use is too soft or too earthy for metal-working, the metalwork will corrode faster. This decreases the longevity and quality of your products.

Corrosion of machinery

Water with the wrong pH balance for metal-working will lead to the corrosion of your machinery. This decreases its lifespan, increases the failure rate and raises costs.

Smell

A common problem with metal-working, which makes your employees’ lives harder, is the smell caused by microorganisms proliferating in the liquids used in industrial processes. This can be prevented by using the proper measures.

Stickiness

Improperly prepared emulsions can get stuck to the machinery, which then requires frequent cleaning. Proper water treatment reduces the stickiness and decreases your maintenance costs.

What will you gain from

proper water treatment

in metal-working?

An advanced system of water treatment in metal-working, from water for cooling and lubricating emulsions to waste water, will immediately reduce your operational costs. You will benefit from reduced maintenance and repair costs and improved working conditions for your employees, and you will eliminate product spoilage and internal quality mismatch.

Want to get a more detailed picture of the advantages and savings that proper water treatment on all levels will bring to your company? Read more about advanced water management throughout your operation.

25 - 30%

Reduction in maintenance costs

10 - 40%

Reduction of energy losses

70 - 75%

Reduction of failure rate

50 - 95%

Reduction of water consumption

35 - 45%

Reduction in planned outages

20 - 25%

Increase in productivity

You can’t step into the same water twice

Water is always water, good old H20. In the real world, though, it has different properties every time, depending on what other substances it contains. Understanding water requires not only a high level of expertise and experience, but also a grasp of each individual situation.

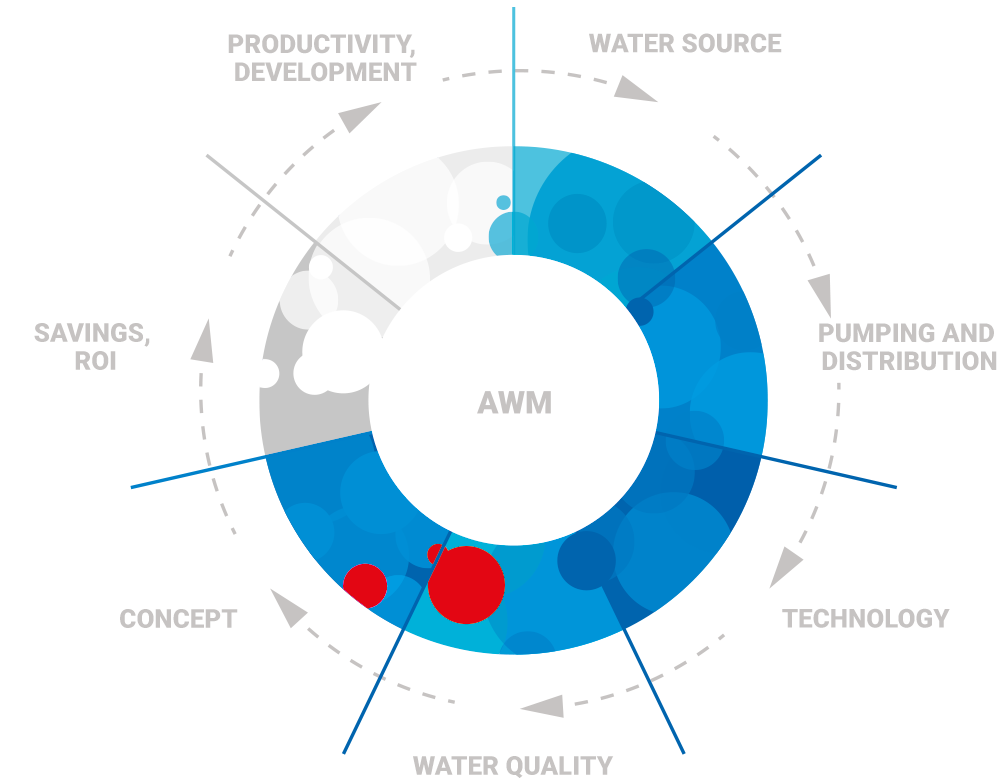

That’s why AWM focuses on the whole water cycle in any given environment. We also look into the future and consider recycling and the maximum possible utilization of water in repeated cycles.

Get to know our customers’ stories

What do they say about us and our work?

What does water affect in your facility?

Download the PDF.