Plastics production

High productivity and a long lifespan for your machinery

At Aquarex, we know that water is a critical part of every system. In injection moulding facilities and other plastic production operations, we usually treat cooling water and processing water.

We manage water for these companies

The most common water-related issues at plastics production plants

- Clogged cooling ducts in the moulds (usually as a result of using water with too high a content of iron or other minerals) that can cause damage or imperfections to the pressings

- Corrosion of mouldings caused by the water chemistry

- Mechanical impurities which clog machinery, mains or heat exchangers and increase wear on the pumps

- Microorganisms and algae accelerate corrosion and clogging, as well as significantly reduce the effectiveness of cooling

- Smelly water (non-treated water in closed circuits)

- Reduced lifespan of equipment and increased maintenance and repair costs

Water from the mains is often too earthy, containing iron and mineral contaminants from piping. This makes it unsuitable for the cooling system. If you use water from your own source (a well, river or rain water), it is necessary to filter and treat it properly.

Properly treated water is essential for the effective operation of all kinds of cooling systems that use water (or a mixture) as their medium.

We often encounter companies that use advanced management systems, have ISO certifications and TMP, use the 5S method and the Kaizen philosophy, but who have overlooked the importance of water and water quality for their technologies.

The quality of the cooling and processing water during plastics production can affect:

- The costs of machinery maintenance and repair

- The frequency of cooling system outages and increased costs of cleaning and replacing components

- The effectiveness of the heat exchange process itself

- Increased electricity consumption

- Increased risk of critical accidents, interruptions of production and increased losses

How do we proceed?

We always start with an on-site inspection. We will let you walk us through your operation, getting to know your technologies and processes so that we can design a custom solution suited to your needs. The composition of the water is unique in any given place, which is why we always take samples and analyse them.

Based on this initial analysis, we recommend suitable technologies, which we supply and set up, then train your employees to operate. Naturally, we also provide after-sale service, with a warranty, support and spare parts supply, which are available immediately.

We design and manufacture the technological systems ourselves.

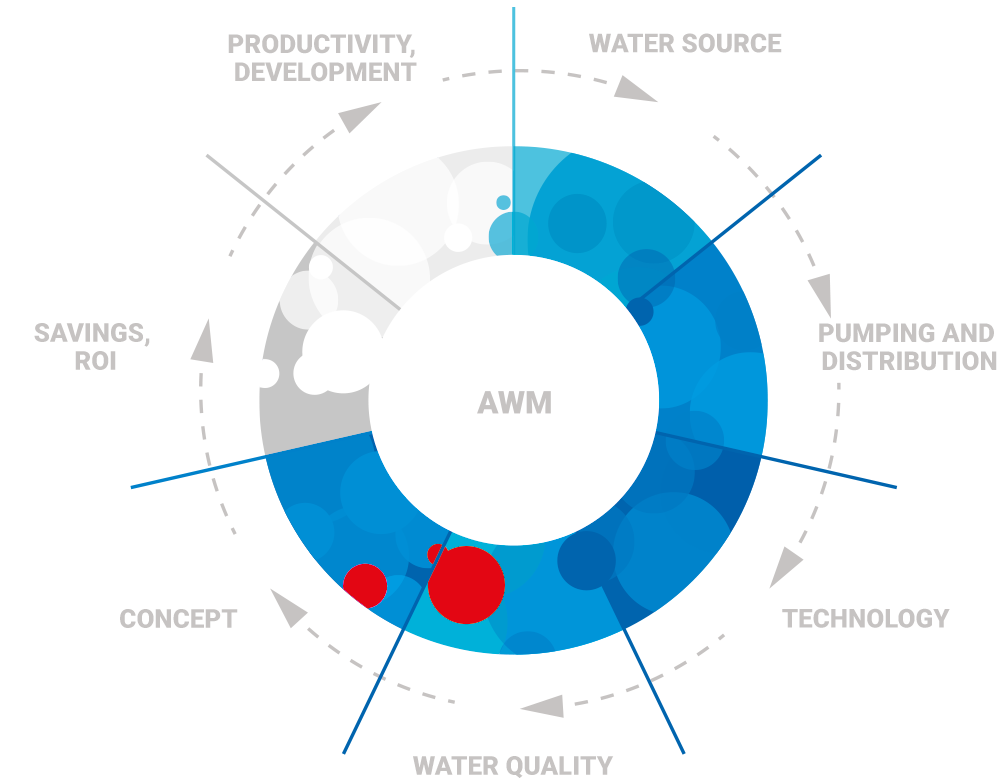

We work to our AWM methodology. Modern water management and quality control is an integral part of our technologies. It can be connected to your SCADA system or our own monitoring system.

What you will gain from

proper water treatment

in plastics production

A sophisticated system of water treatment in plastics production, from water for cooling and lubricating emulsions to waste water, will immediately reduce the operational costs. Equipment maintenance and repair costs will go down, you will eliminate product spoilage and internal quality mismatch, extend the lifespan of your machinery and improve working conditions for your employees.

Want to get a more detailed picture of the advantages and savings that proper water treatment on all levels will bring to your company? Read more about advanced water management throughout your operation.

25 - 30%

Reduction in maintenance costs

10 - 40%

Reduction of energy losses

70 - 75%

Reduction of failure rate

50 - 95%

Reduction of water consumption

35 - 45%

Reduction in planned outages

20 - 25%

Increase in productivity

Get to know our customers’ stories

What do they say about us and our work?

What does water affect in your facility?

Download the PDF.