Cooling water treatment

Cooling water treatment

Many industrial facilities rely on effective cooling to function properly. Today’s trend is not only to reduce the consumption of water during cooling, but also to optimise its quality and environmental friendliness.

A good cooling water treatment provides operational efficiency, reliability and increases the lifespan of your machinery.

Water treatment for cooling systems

Water treatment is an indispensable part of any cooling system. This is especially true in cooling systems using cooling towers or micro towers with both natural or forced draft.

Just 0.1 mm of sediment can reduce the efficiency of the heat exchange process by more than 20 %. A deposit of biological film is an even stronger insulant. In improperly treated cooling system, deposits of more than 0.5 mm can accrue every year. Not treating cooling water properly means that companies literally throw money away due to ineffective heat exchange.

The most frequent problems we encounter in cooling systems

- Corrosion – corrosion causes sediments to be released into water and the system becomes clogged

- Sediments – these build up on the walls of plumbing and heat exchange surfaces, creating a layer that reduces efficiency

- Clogging – dirt and sand, dust, byproducts of corrosion and natural organic materials

- Microbiological contamination, biofilm – bacteria, algae

What’s our solution?

We will provide a complete water treatment both on entry and inside the system. This includes automated water quality monitoring, deluge, deaeration and of course an automated supply of treated water into your cooling system.

Because there is no universal solution, we will start with a visit to your operation and conduct a water analysis.

Overview of technologies we use for cooling water treatment

- Automated electronically or hydraulically operated mesh filters for removing debris

- Media filters with various filter beds according to the type and purpose

- Water softening stations, removing iron and manganese, plus reverse osmosis units for the pre-treatment of cooling water

- Chlorine dioxide generators OxiPerm Pro for eliminating microbiology, biofilms and legionella

- Dispensing stations for corrosion inhibitors, biocides and other corrective chemicals

- Measuring and regulating technologies for monitoring and assessing the water quality and controlling the dosage

We don’t underestimate the risk that legionella pneumophila represents in cooling towers, and we make sure that our client takes care of this area as a part of their risk management. The aerosol from a cooling tower may, under the right circumstances, reach areas up to several kilometres away, endangering anyone who inhales it.

When designing technologies for the effective treatment of water in cooling, we focus on the operational effectivity, efficiency and environmental friendliness of the whole solution. We provide an extended warranty for the technology, with our maintenance.

We provide water solutions for the following companies

What you will gain with

a proper cooling water treatment

A sophisticated system of cooling water treatment will immediately reduce your operational costs. Equipment maintenance and repair costs will go down, you will eliminate product spoilage and internal quality mismatch, extend the lifespan of your machinery and improve working conditions for your employees.

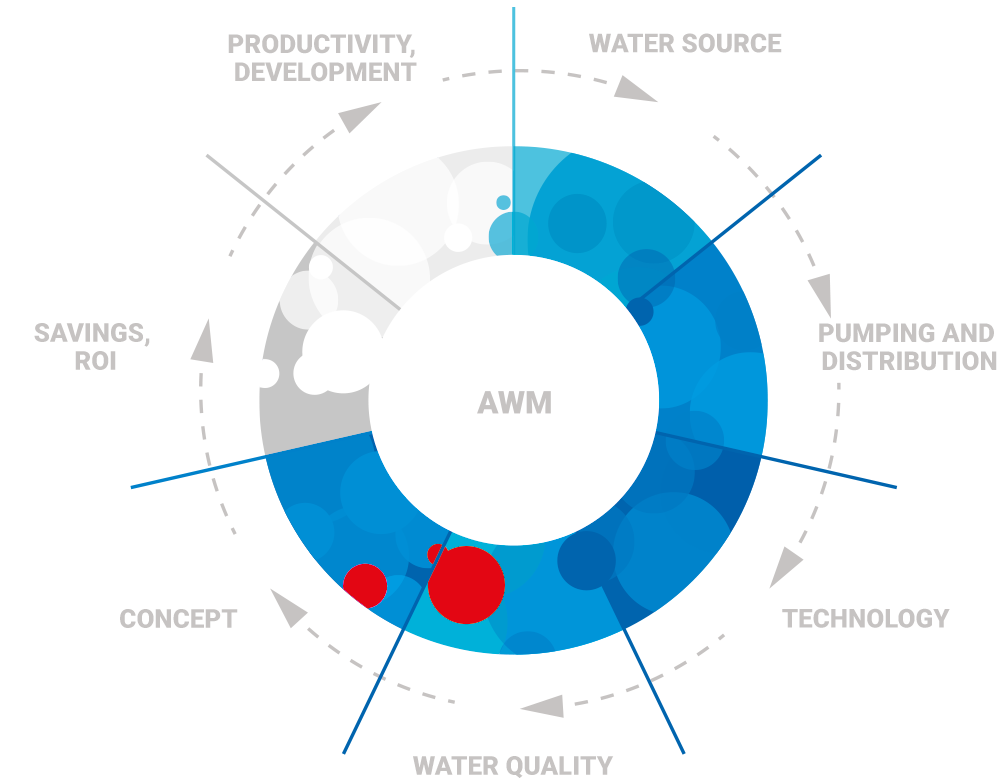

Do you want to get a better picture of the gains and savings that proper water treatment on all levels will bring? AWM is focused on water’s whole lifecycle in any given environment. We are looking into the future, considering recycling and the maximum utilization of water in repeated cycles.

Get to know our customers’ stories

What do they say about us and our work?

What does water affect in your facility?

Download the PDF.